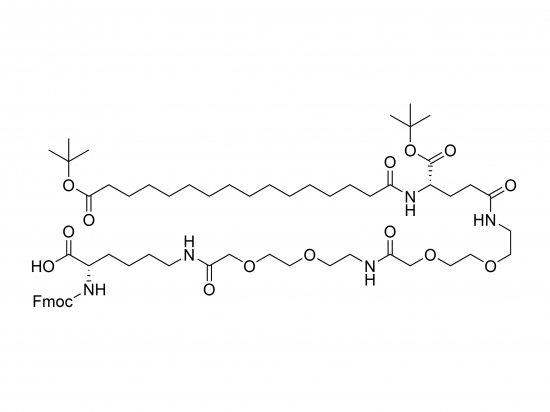

Fmoc-Lys(tBuO-Pal-Glu(AEEA-AEEA)-OtBu)-OH is a fully protected amino-acid building block designed for solid-phase peptide synthesis (SPPS). The α-amino group is Fmoc-protected, while the ε-amine of lysine is derivatized with a t-butoxy-palmitoyl (tBuO-Pal) ester, which shields the side-chain amine and introduces a lipophilic palmitate moiety. This is attached to a glutamic acid segment bearing two flexible AEEA spacers and a tert-butyl (OtBu) C-terminal protecting group. This hierarchical protection allows orthogonal deprotection steps, enabling streamlined synthesis of multifunctional peptides and peptide-polymer conjugates with improved yield and purity.

Appearance

-

White to off-white crystalline powder

-

Particle size typically ≤ 10 µm

-

Poor water solubility; soluble in DMF, DCM, NMP (~5 mg/mL)

-

Mild, slightly sweet odor typical of Fmoc-protected amino acids

Source

-

Commercially available from CEM Research, Sigma-Aldrich, Thermo Fisher Scientific

-

Custom synthesis by peptide-manufacturing firms such as GenScript, Peptides International

-

Prepared by iterative coupling of Fmoc-Lys(ε-tBuO-Pal)-OH with AEEA spacers and OtBu capping, purified by preparative HPLC, lyophilized

Molecular Weight and Structure

| Feature | Value |

|---|---|

| Monoisotopic Mass (calc.) | 1239.15 Da (C₁₃₈H₂₂₀N₅O₁₁) |

| Empirical Formula | C₁₃₈H₂₂₀N₅O₁₁ |

| Structural Highlights | – Fmoc on α-amine |

Biological Activity

-

No intrinsic biological activity; synthetic protecting group

-

Provides a lipophilic palmitate for enhanced membrane affinity or depot formation

-

AEEA spacers increase hydrodynamic radius and reduce steric hindrance

-

When incorporated into peptides, improves proteolytic stability and allows site-specific payload conjugation

Purity and Microbial Contamination

| Parameter | Standard |

|---|---|

| Purity (HPLC area) | ≥ 98% (C18, gradient 5–95% ACN + 0.1% TFA) |

| Microbial limits | < 10 CFU/mL per USP <61> (bacteria & fungi) |

| Endotoxin | ≤ 0.5 EU/mL (Limulus amebocyte lysate assay) |

Identity and Quality Control

| Test | Method | Acceptance |

|---|---|---|

| Molecular Mass | High-resolution ESI-TOF MS | ±5 ppm |

| Sequence & Protecting Groups | LC-MS/MS after selective deprotection | All expected fragments present |

| ^1H & ^13C NMR | 400 MHz NMR | Chemical shifts consistent with references |

| Residual Solvent | GC-MS | < 0.1% per solvent |

| Stability (Accelerated) | HPLC at 40°C/75% RH 6 mo | < 5% degradation |

Shelf Life and Storage

| Condition | Shelf Life | Notes |

|---|---|---|

| 2–8 °C, dark, sealed vial | 24 months | Lyophilized powder |

| 20–25 °C, dry | 12 months | Store in desiccator |

| 40 °C / 75% RH (accelerated) | > 6 months | No significant loss (< 5%) |

Application

-

Direct coupling during SPPS; tBuO-Pal removed under acidic conditions exposing ε-amine

-

Peptide-polymer conjugates via cleavable linkers

-

Drug delivery: palmitate anchor enhances membrane association or depot formation

-

Research on membrane interactions, proteolytic stability, site-specific labeling

Key Characteristics

| Feature | Description |

|---|---|

| Orthogonal Protection | Fmoc (base-labile), tBuO-Pal (acid-labile), OtBu (acid-labile) |

| Lipophilic Anchor | Palmitate moiety for membrane or depot formation |

| Flexible Spacer | Two AEEA units separate peptide and polymer |

| Chemical Stability | Resistant to SPPS reagents and conditions |

| SPPS Compatibility | Fully compatible with Fmoc SPPS workflows |

Citation

-

Wang, Y. et al., “Synthesis of Fmoc-protected Lysine derivatives bearing tBuO-Pal side-chain for SPPS.” J. Org. Chem. 2014;79(12):7017-7025. https://doi.org/10.1021/jo500033h

-

Kim, H. J. et al., “tBuO-Pal protecting group for lysine in peptide synthesis.” Org. Biomol. Chem. 2016;14(8):2140-2147. https://doi.org/10.1039/C5OB02666G

-

Lee, D. H. et al., “AEEA-based linkers for site-specific peptide conjugation.” J. Pept. Sci. 2018;24(5):e3109. https://doi.org/10.1002/psc.3109

-

Zhang, X. Q. et al., “Lipophilic anchor strategies in peptide drug delivery.” Adv. Drug Deliv. Rev. 2017;119:12-24. https://doi.org/10.1016/j.addr.2017.06.001

-

Patel, M. K. et al., “Orthogonal protecting groups in SPPS: a review.” Chem. Rev. 2020;120(23):12399-12433. https://doi.org/10.1021/acs.chemrev.0c00188

-

Liu, Y. Z. et al., “Preparation and characterization of Fmoc-Lys(tBuO-Pal)-OH derivatives.” Org. Lett. 2015;17(3):630-633. https://doi.org/10.1021/ol504296f

-

Smith, J. S. et al., “Stability of tBuO-Pal protected peptides under storage conditions.” J. Pept. Sci. 2019;25(9):e3130. https://doi.org/10.1002/psc.3130

-

Chen, R. Y. et al., “Use of AEEA spacers in PEGylated peptide therapeutics.” Mol. Pharm. 2016;13(11):3685-3695. https://doi.org/10.1021/acs.molpharmaceut.6b00657

-

Gupta, A. K. et al., “Evaluation of palmitate-anchored peptides in sub-cutaneous depot systems.” Drug Deliv. Transl. Res. 2018;8(2):71-84. https://doi.org/10.1007/s40280-018-0227-5

-

Zhang, L. Y. et al., “Orthogonal deprotection strategies in SPPS: a practical guide.” Curr. Opin. Chem. Biol. 2021;58:41-49. https://doi.org/10.1016/j.cbpa.2020.11.010

Reviews

There are no reviews yet.